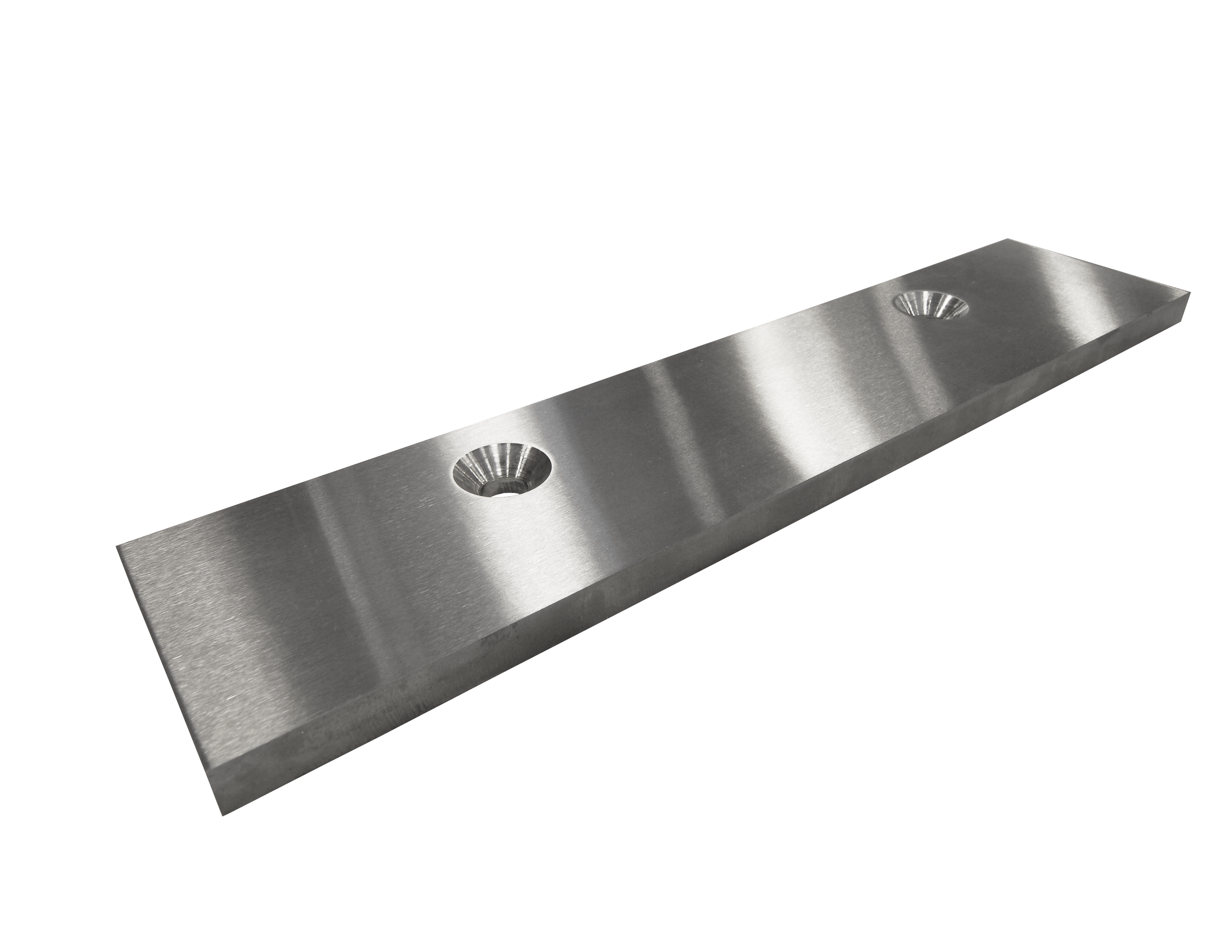

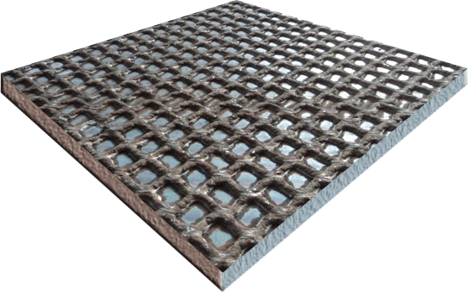

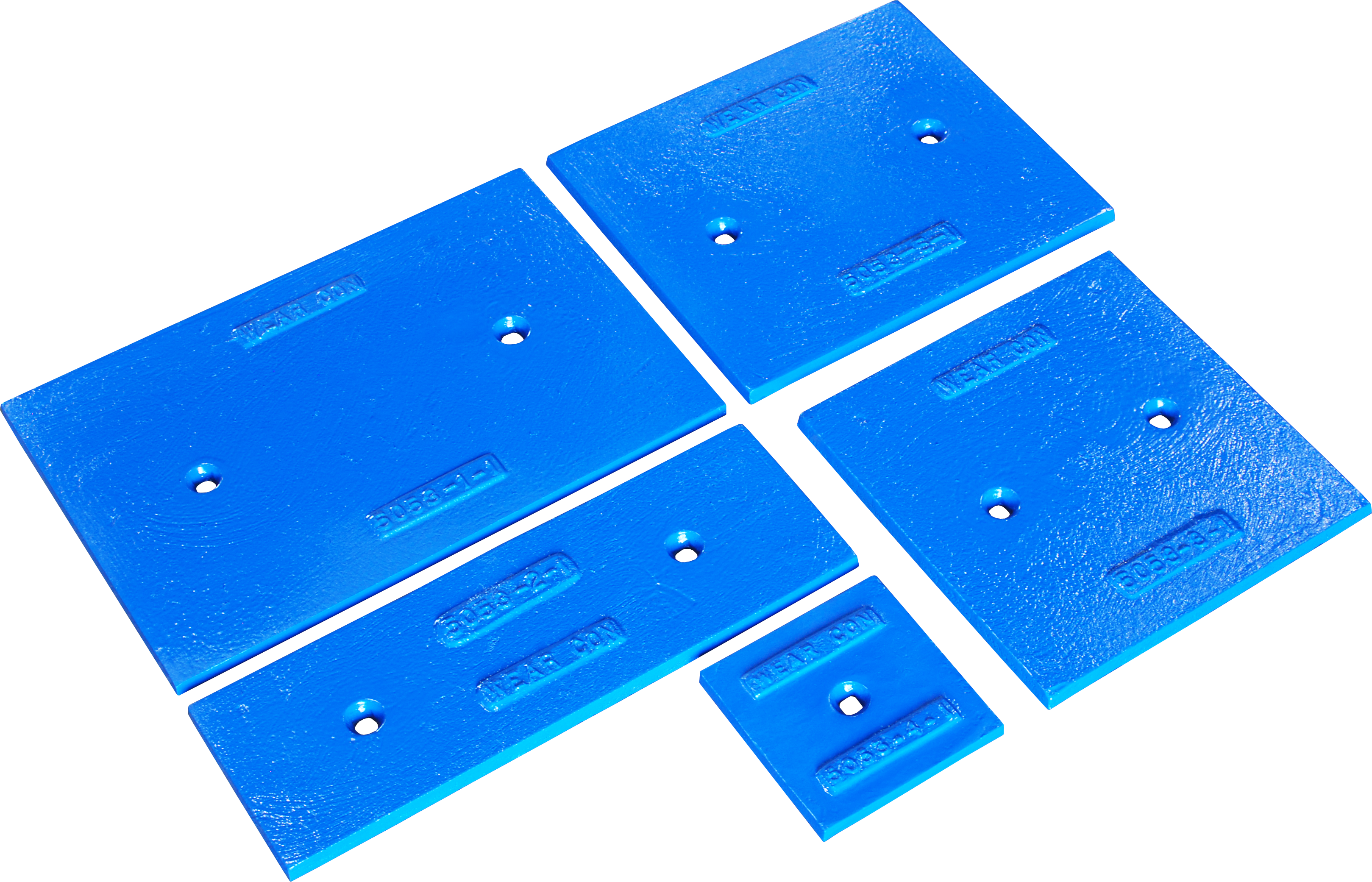

Features & Benefits

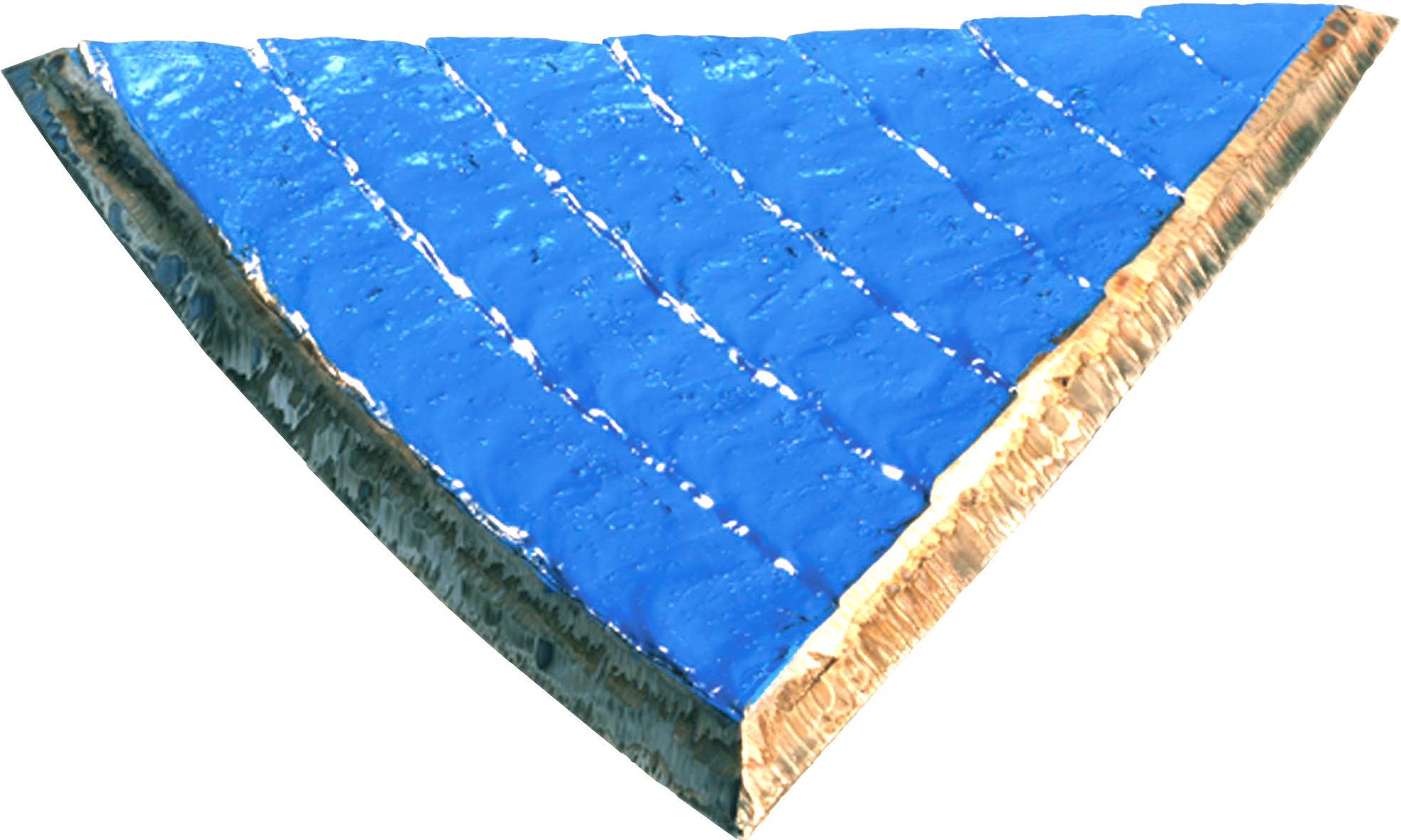

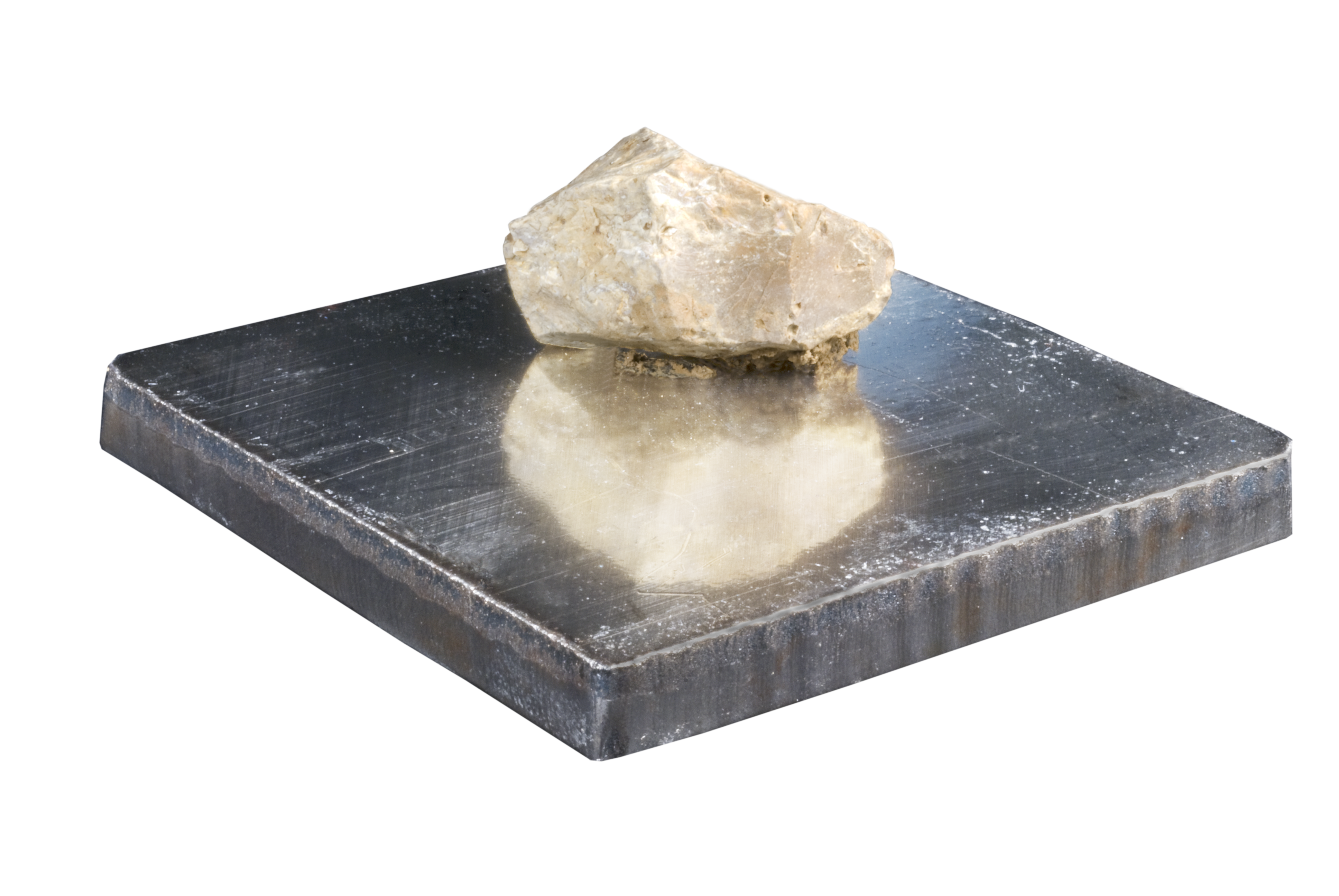

Wear-Con Gardian™ 12% Chromium Utility Grade Ferritic Stainless Steel Wear Plate’s yeild strength is approximately 85% higher than that of austenitic stainless steels such as grades 304L and 316L. Gaurdian™ has a large yeild strength advantage over mild steel and A36 grade steels as well. The main advantage of Gaurdian™ over other ferritic stainless steels is that it is very tough, even when welded. In thicknesses of up to 30mm and retains its toughness at temperatures below the freezing point. Gaurdian™ has also found widespread use in wet sliding abrasion conditions and in aqueous environments involving exposure and/or immersion.

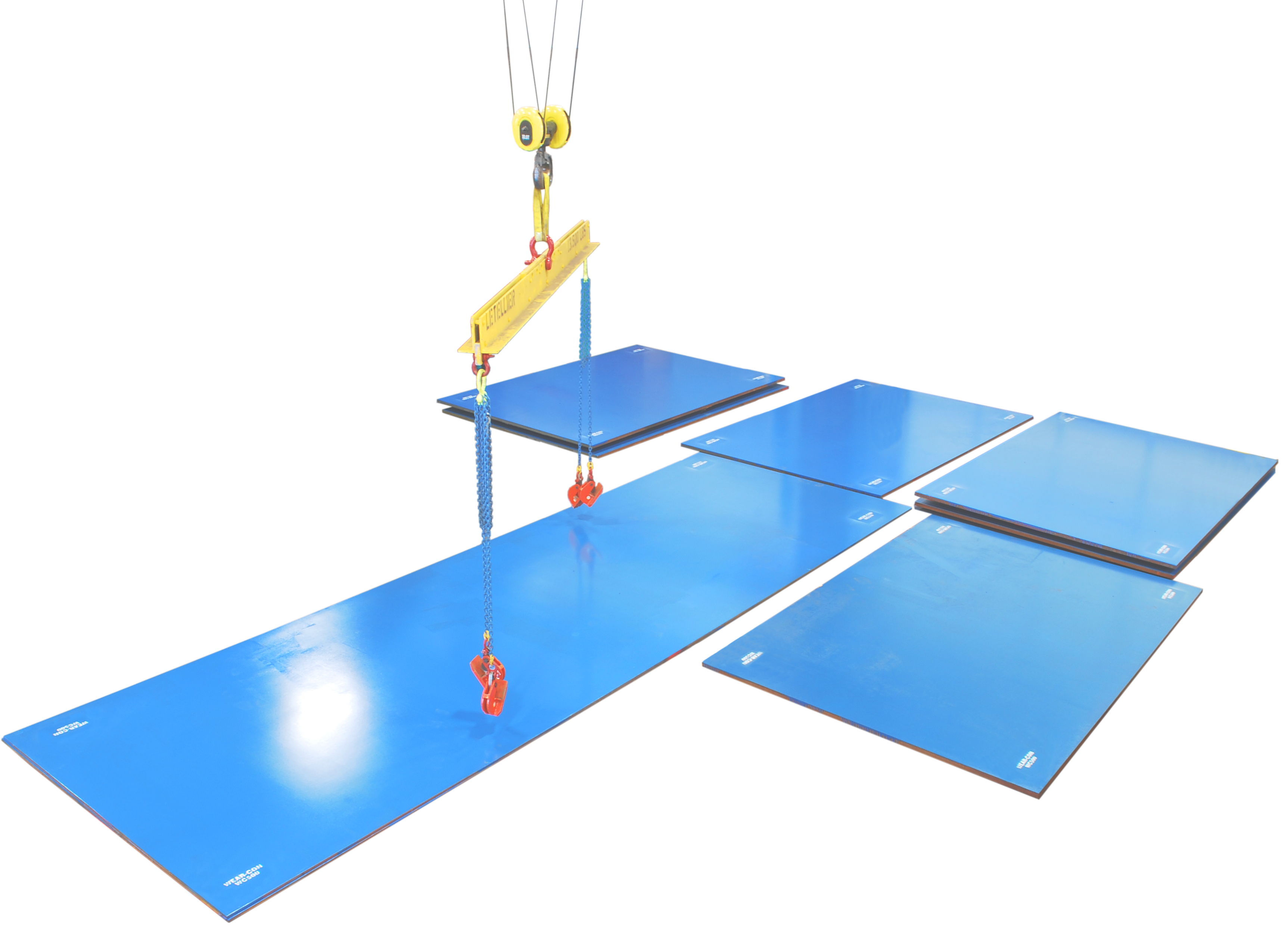

Installation

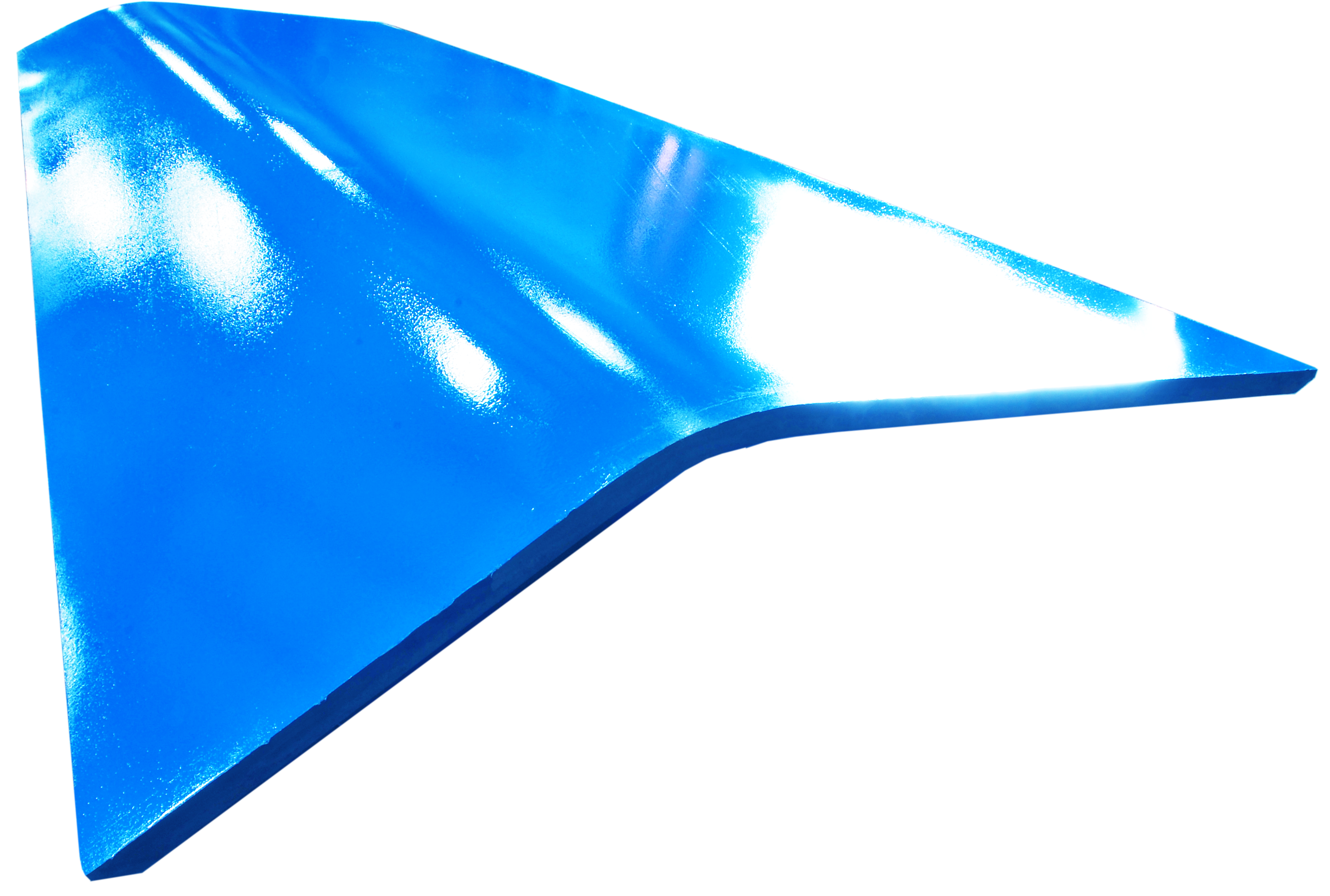

Wear-Con Gaurdian™ can be formed, rolled, and cut to your specific needs. Gaurdian™ has good weldability and is suited to most standard welding methods. It can be welded to other ferrous metals, for example mild and stainless steels, quite satisfactorily. The recommended grade of electrode is the AWS 309L type. When welding Gaurdian™ to itself, E308L or E316L can also be used. The heat input should be controlled to between 0.5kJ/mm and 1.5kJ/mm per pass.

Technical Specifications

Wear-Con Gaurdian™ is significantly more corrosion resistant than mild or low alloy corrosion resistant steels. Gaurdian™ should only be used in mildly corrosive conditions. Pitting corrosion is possible in applications involving contact with chloride solutions, particularly in the presence of oxidizing media. However, Gaurdian™ does not lose its impact resistance at this temperature range. Heat Resistance: Gaurdian™ stainless steel exhibits scaling resistance between 600 and 750°C in the presence of air, and between 450 and 600°C under stress environments. The material tends to become fragile upon prolonged exposure to temperatures between 450 and 550°C. However, Gaurdian™ does not lose its impact resistance at this temperature range.

Sizes

Gaurdian™ Sheets are 1/4” thick x 60” wide x 120” long.